TECHNOLOGY

The future is here. Accelerating today’s innovations in grid modernization and infrastructure advancement

- TX SYSTEM

Technology

Tool of the Future

The TX System incorporates industry first technology designed to mitigate risk, reduce cost and increase efficiency of power line installation.

Built tough in Australia and battle tested by industry leaders around the world, Infravision’s TX System is purpose built for safe, fast, green and scalable aerial power line installation.

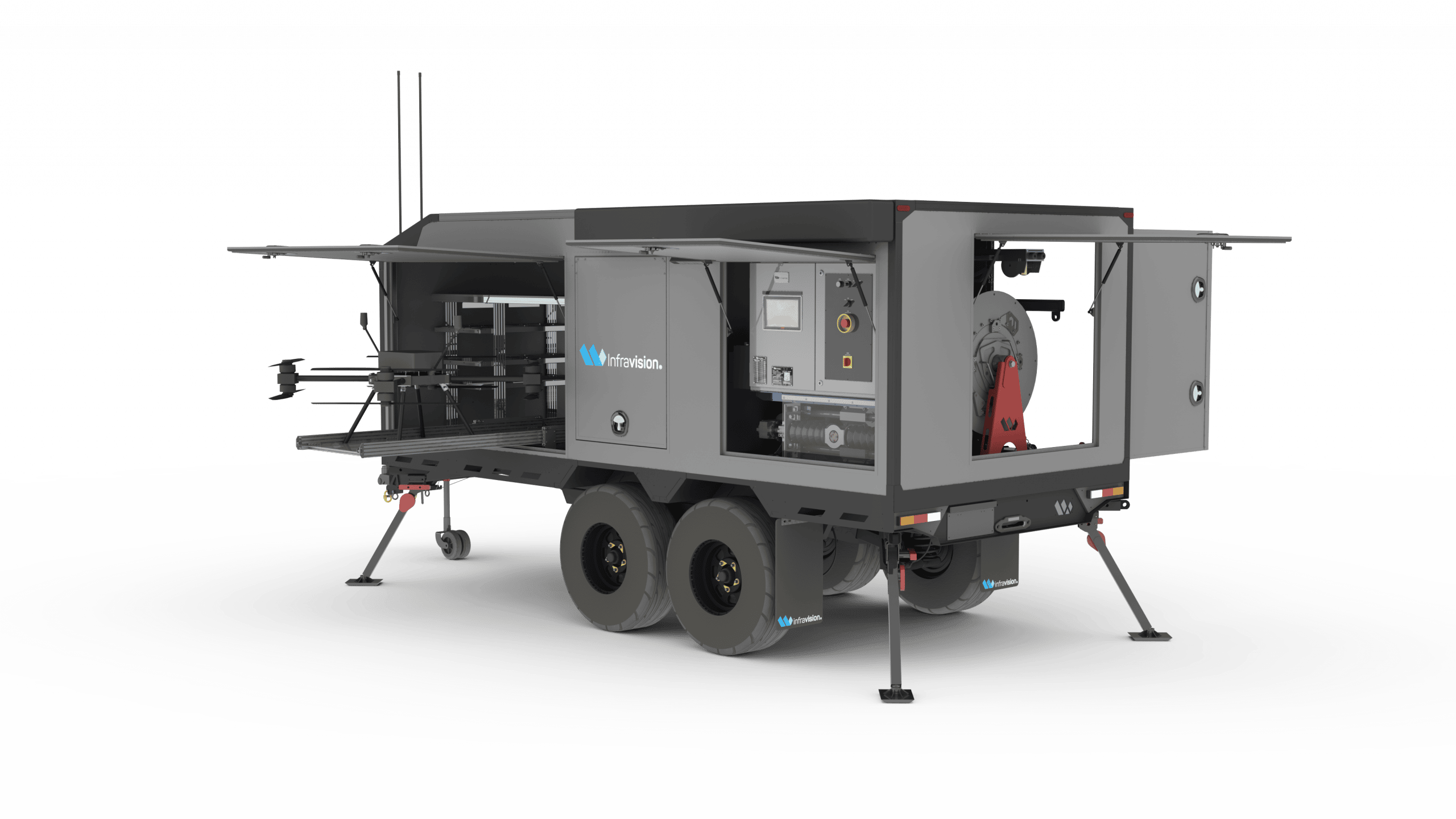

The TX System combines a stringing drone with an electric smart puller tensioner bundled into a compact tough off road trailer capable of deploying to both urban and remote locations.

As electric utilities look to the challenges of the future, the TX System is a multipurpose tool in the delivery of high quality energy outcomes providing a safe, fast, low impact and cost effective alternative to unlock workforce capacity and enhance emergency response and disaster preparedness.

THE TX SYSTEM

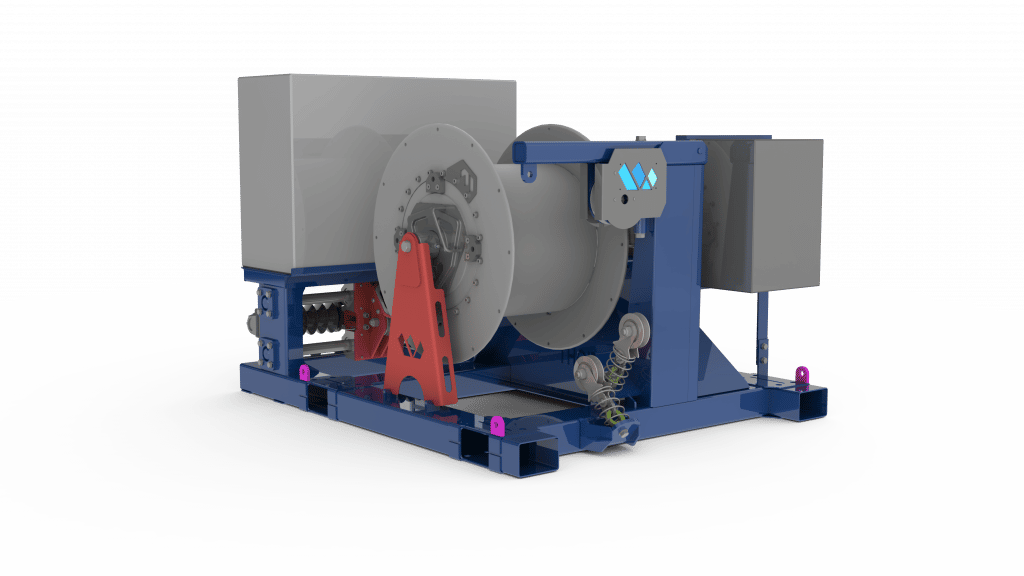

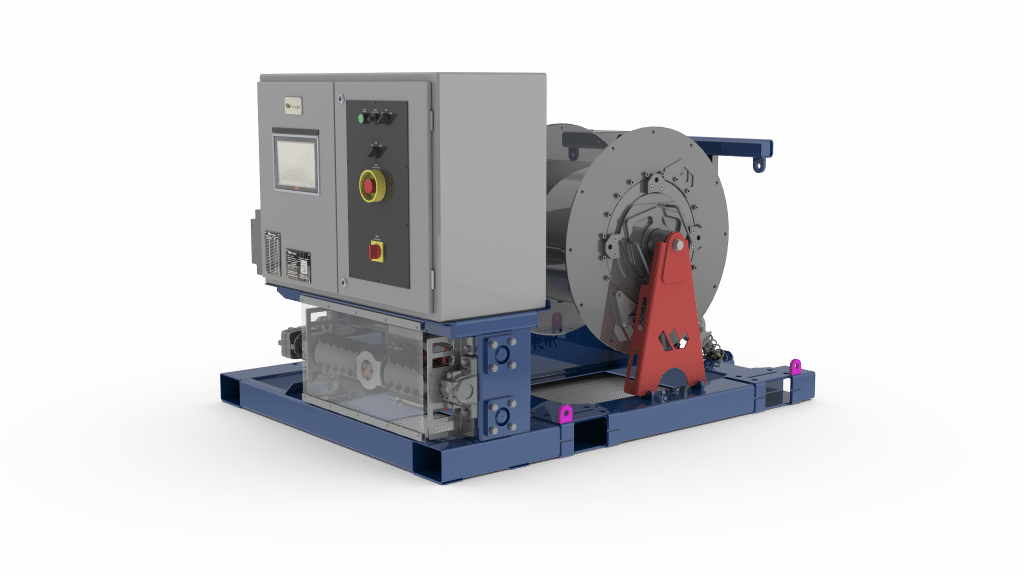

Smart puller tensioner

Infravision’s Thor electric pullers do the work of standard industry stringing helicopters.

The heart of the TX System

While stringing, Infravision’s Thor electric puller tensioner will automatically pay out line to the UAS and haul back conductor, draw wire or synthetic pull line.

Our Benefits

SAFE

The TX System eliminates most critical risks present in close proximity operations, minimizes exposure to heights, and lowers the overall use of plant and equipment interactions with workers on a site.

FAST

The TX System can string up to 10 mi / 16 km of line per day, with the ability to scale TX Systems to match productivity objectives.

LOW COST

Accelerated construction times, reduced labor resources required, elimination of environmental clearing costs, less downtime of network, reduced skilled labor cost.

GREEN

Preservation of vegetation and natural environment which would otherwise be impacted using traditional construction methods. The TX System reduces emissions. Infravision leverages electric drone and winch technology which means an 8x reduction in emissions compared to helicopters.

COMMUNITY IMPACT

Low impact on community and culturally significant sites. Less power outages and construction impacts such as noise, vibration and site office presence. Using drone technology can also help save vast amounts of wildlife and help to preserve plants and animals.

“If we are going to be successful as an industry we have to innovate, we have to disrupt the way we’re doing it, and I want to use Infravision as an example of that”

CRAIG STALLAN

Executive General Manager for Delivery, Transgrid

Trusted by the world's best

Widely adopted

The TX System has been widely adopted in Australia and has delivered 100% of aerial power line stringing for utility owner operators since 2020. Launched in the United States in 2022, the TX System has been embraced by the North American market and adopted by major utilities such as Pacific Gas & Electric, one of the largest combined natural gas and electric energy companies nationwide.